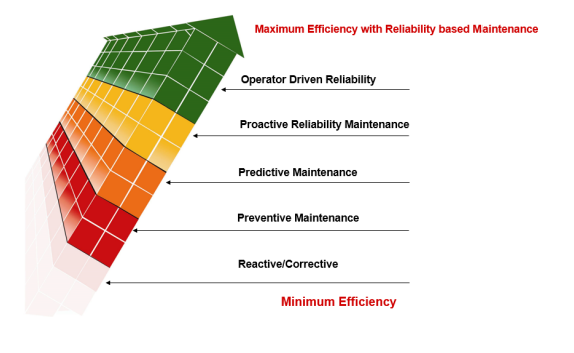

Today, a factory's assets play a key role in the overall efficiency of companies and manufacturing plants. This is why more and more production companies are turning to reliability-based maintenance (RBM) as a strategy to help preserve valuable factory assets and eliminate the costly negative impacts of operational issues such as delays, downtimes, and unexpected failures. Many organizations make significant efforts to manage preventive maintenance and keep up with the complexities of operational assets. Without implementing a systematic, multi-faceted reliability process for asset management, these companies often resort to random trial-and-error activities to achieve their maintenance goals, resulting in wasted resources and disappointing outcomes. By implementing reliability-based maintenance (RBM) within their operations, companies can effectively prevent these unwanted situations and optimize asset performance.

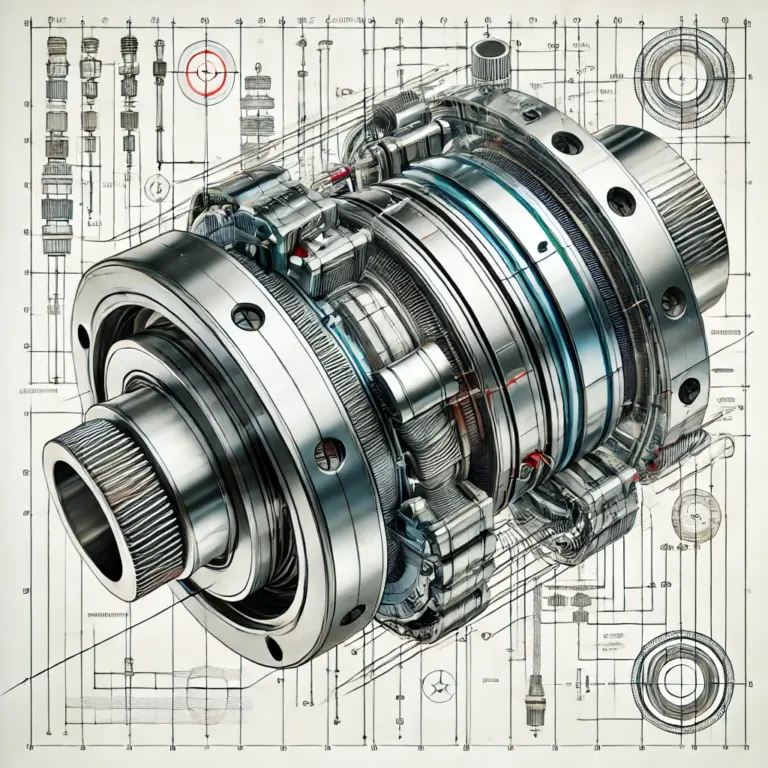

Avoiding Dry Gas Seals (DGS) Contamination

According to existing standards for various operational conditions in the oil, gas, refining, and petrochemical industries, dry gas seal (DGS) systems are among the most critical and sensitive components of