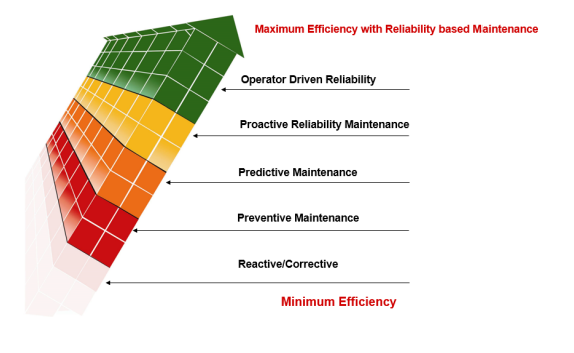

7 Steps to Implement Reliability-Based Maintenance (RBM)

Today, a factory’s assets play a key role in the overall efficiency of companies and manufacturing plants. This is why more and more production companies are turning to reliability-based maintenance (RBM) as a strategy to help preserve valuable factory assets and eliminate the costly negative impacts of operational issues such as delays, downtimes, and unexpected failures. Many organizations make significant efforts to manage preventive maintenance and keep up with the complexities of operational assets. Without implementing a systematic, multi-faceted reliability process for asset management, these companies often resort to random trial-and-error activities to achieve their maintenance goals, resulting in wasted resources and disappointing outcomes. By implementing reliability-based maintenance (RBM) within their operations, companies can effectively prevent these unwanted situations and optimize asset performance.

Avoiding Dry Gas Seals (DGS) Contamination

According to existing standards for various operational conditions in the oil, gas, refining, and petrochemical industries, dry gas seal (DGS) systems are among the most critical and sensitive components of centrifugal compressors in operational units. Given the key role of centrifugal compressors in most operational units, the direct impact of their operational reliability on the overall reliability of these units is undeniable. One of the most important factors influencing the proper operation of compressors is the performance of dry gas seal (DGS) systems. The primary cause of failure in these systems is the ingress of contaminants into the stuffing box, including moisture, suspended particles, and various impurities. This article aims to explain the importance of preventing such occurrences.

A Guide to Life Cycle Cost (LCC) Analysis for Pumping Systems

Pumping systems account for approximately 20% of the world’s electrical energy demand and nearly 25% of the energy consumed in industrial plant operations is dedicated to pumping systems. These systems are widely used across various industries. The energy and materials used in a pumping system depend on pump design, system design, installation design, and the way they are operated. Life cycle cost (LCC) analysis of equipment is a management tool that can help companies minimize waste and maximize energy efficiency for many systems, including pumping systems.

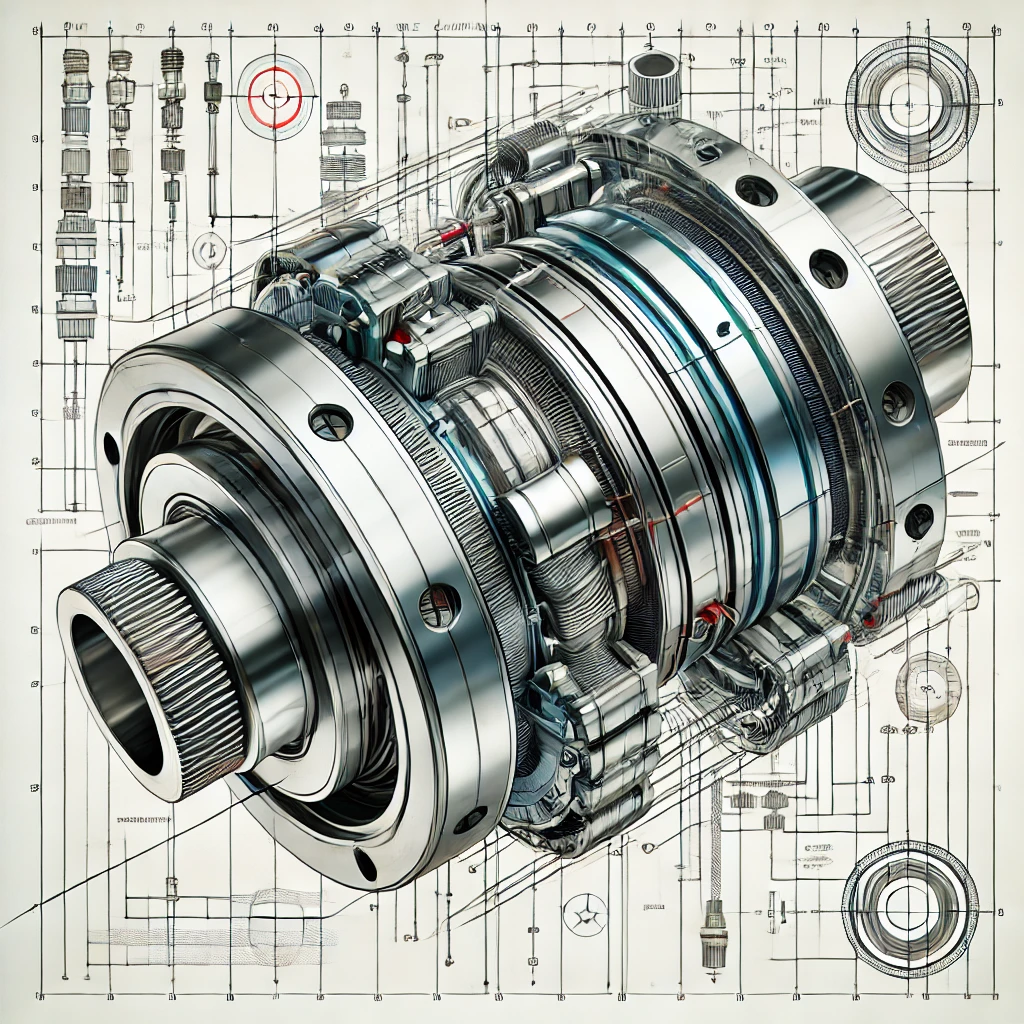

Flexible Coupling Failure Analysis

A coupling is a device used for two main purposes in rotating machinery: connecting the driving machine to the driven machine and transmitting torque from the driving machine. Given that rotating machines are usually operated at relatively high speeds, factors such as vibration loads and misalignment loads are critical parameters influencing the design of this product.

Typically, couplings do not allow shafts to separate during operation; however, torque-limiting couplings can slip or disengage when the torque exceeds a certain threshold.